The corona gun is most often utilized and operates on imparting a negative electrostatic charge to your powder particles. Soon after obtaining the charge, these particles are shot within the aspect to be coated by way of compressed air or mechanical motion.

A fluidized bed is essentially a tub of powder with air flowing through it. Aerated powder behaves just like a fluid, which permits components to become dipped into it.

Rinsing: After cleaning and pretreatment ways, assure comprehensive rinsing to get rid of any residual chemical compounds or contaminants. Contaminants left behind can have an affect on the adhesion and efficiency in the powder coating.

To grasp the intricacies of this method, delve into our in-depth web site regarding the two coat system for insights and guidelines.

When applying powder coating or standard paint employing a spray gun, a large amount of materials is probably going squandered as “overspray.” This refers back to the portion of fabric dispensed with the spray gun that by no means reaches the intended surface.

You can also coat metals like brass, copper, bronze and so forth. to stop them from oxidation. You can also powder coat stainless steel to reinforce the rust resistance of your metal alloy.

An additional means of preparing the surface area before coating is referred to as abrasive blasting or sandblasting and shot blasting. Blast media and blasting abrasives are utilised to offer floor texturing and preparing, etching, finishing, and degreasing for items product of Wooden, plastic, or glass.

Mechanical cleansing may be used independently or along with a chemical treatment method. When it improves adhesion, it doesn't provide more corrosion protection.

Example of powder coating spray guns The commonest means of implementing the powder coating to metal objects is usually to spray the powder working with an electrostatic gun, or corona gun. The gun imparts a detrimental charge on the powder, which happens to be then sprayed to the grounded object by mechanical or compressed air spraying after which you can accelerated toward the workpiece from the highly effective electrostatic cost. There's a wide variety of spray nozzles accessible for use in electrostatic coating.

The choice of las vegas powder coating substrates performs an important purpose in figuring out the final complete, durability, and suitability for a variety of applications. In this article, we will discover a number of the most common powder coating substrates and delve further into their exclusive traits and makes use of.

Powder Spray Booth: This serves since the workspace for making use of the powder product to a part. What's more, it functions being an air filter and overspray containment and Restoration technique.

Generally, metallic pieces are chemically handled in procedures named phosphating and chromating. Listed here, the metals are dipped in corrosive acids to get a predetermined, concise time, after which they’re rinsed and dipped in phosphate or chromate methods. This enhances the subsequent bond among the metal and powder, strengthening the surface complete and products overall performance.

Warmth-delicate carbon fiber tubes coated having a UV curable powder coating. Powder coating is often a sort of coating which is applied to be a free-flowing, dry powder. Contrary to traditional liquid paint, which happens to be sent by means of an evaporating solvent, powder coating is often applied electrostatically after which you can cured less than warmth or with ultraviolet mild. The powder may be a thermoplastic or possibly a thermosetting polymer.

This distinctive adherence method makes sure a solid bond in between the coating along with the substrate, resulting in a thick, strong complete that resists scratching, chipping, fading, and use from severe environments and hefty utilization.

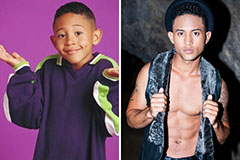

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!